Introduction to the globally popular track sockets & How to install them?-1

Track Socket Systems originated from industrial electric rail design. After iterative adaptation for civilian use, it has now become a preferred component in modern building electrical schemes, especially favored by high-end residential and commercial spaces in Europe and America. Its innovation lies in:

Dynamic Power Supply Network: The mobile adapter (Power Carrier) enables users to freely add or remove, and position the socket modules, adapting to changes in equipment layout.

Redundant Safety Design: Integrated with overload protection, arc fault detection (AFCI), and temperature monitoring, it complies with the multi-region certification system of IEC/UL/CE.

Applicable Scenario Examples

European open kitchen: Compatible with 230V voltage standard, capable of supporting simultaneous operation of multiple high-power devices (>3kW)

North American home office area: Compliant with NEC 2023 wiring specifications, supporting USB-C 100W fast charging module expansion

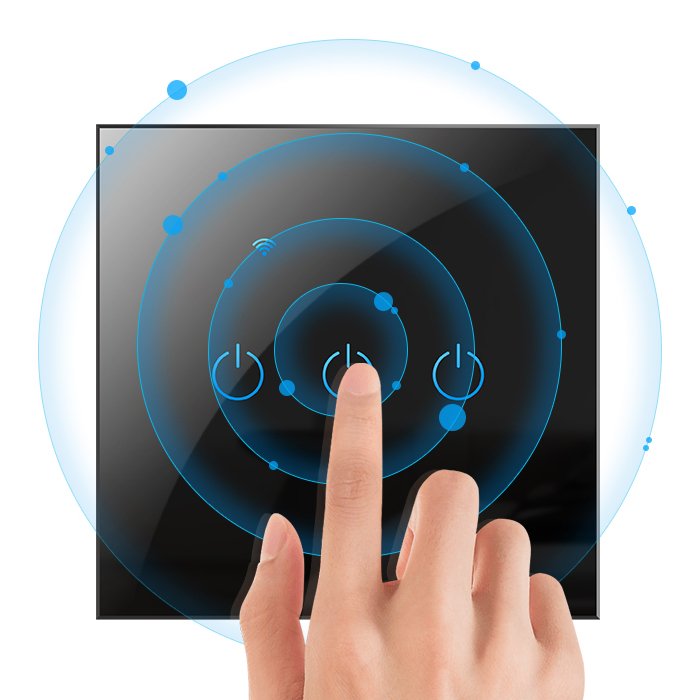

All-round wiring

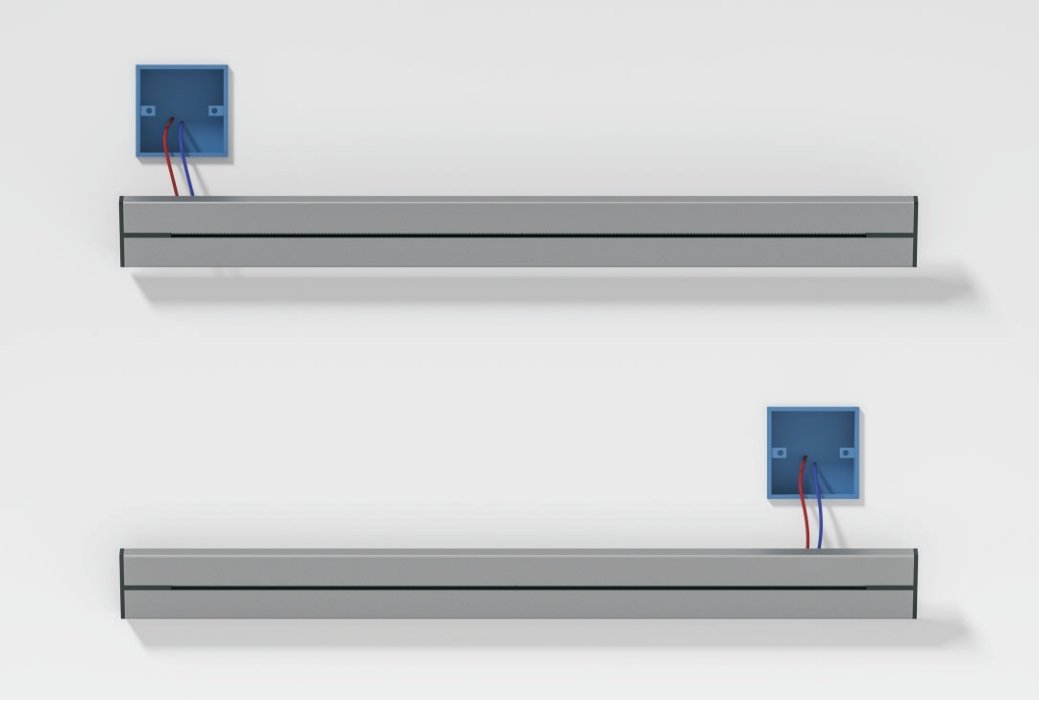

The track unilateral terminal can realize 360° all-round coverage wiringYou can choose the corresponding locationaccording to the specific situation of your home.

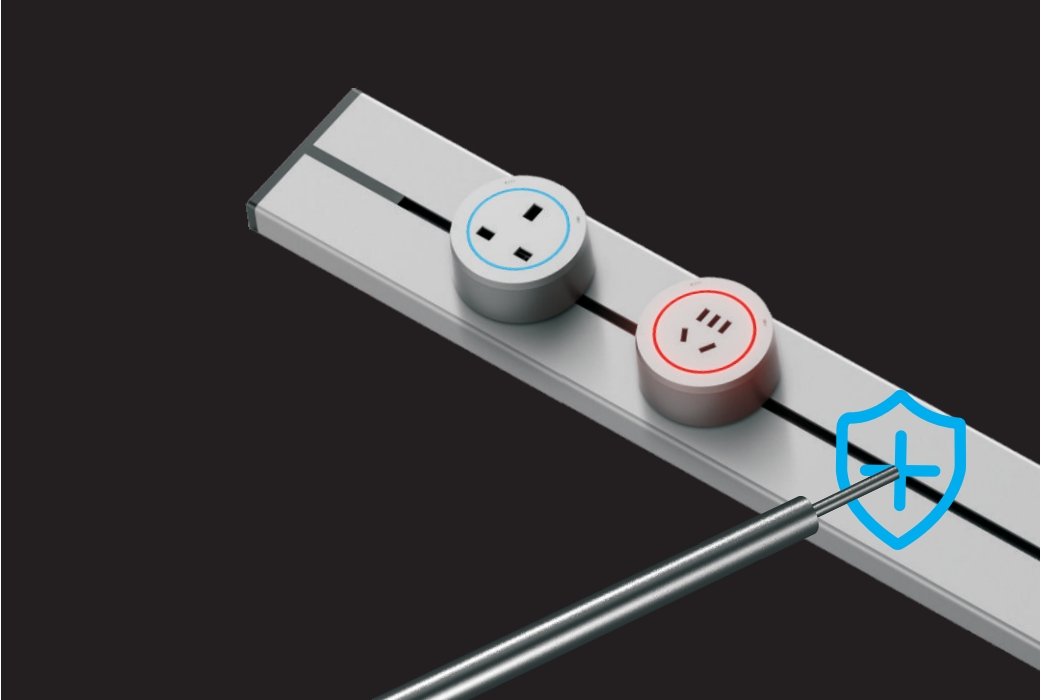

Waterproof, dustproof and electric

All conductors are wrapped with flame-retardantinsulators,and the zero fire line is concealed at the upper end of the track.High resilience airtight rubber strip prevents fingers and dust from penetrating in,It won’t be deformed after long time use, preventing the possibility of electric shock.

The track socket can replace the original socket.

The old sockets are outdated in appearance, lack fashionable design, have only one function and are not practical to use. Moreover, they are made of thin materials and not durable.

The wall-mounted track sockets can cover the original socket boxes, achieving a seamless and more aesthetically pleasing installation. The wires of the original socket boxes can be connected directly for universal use, making the installation convenient and easy.

Modular design, flexible and convenient, comprehensive in functions, ready-to-use and add-on.

Specification of the track socket And the module

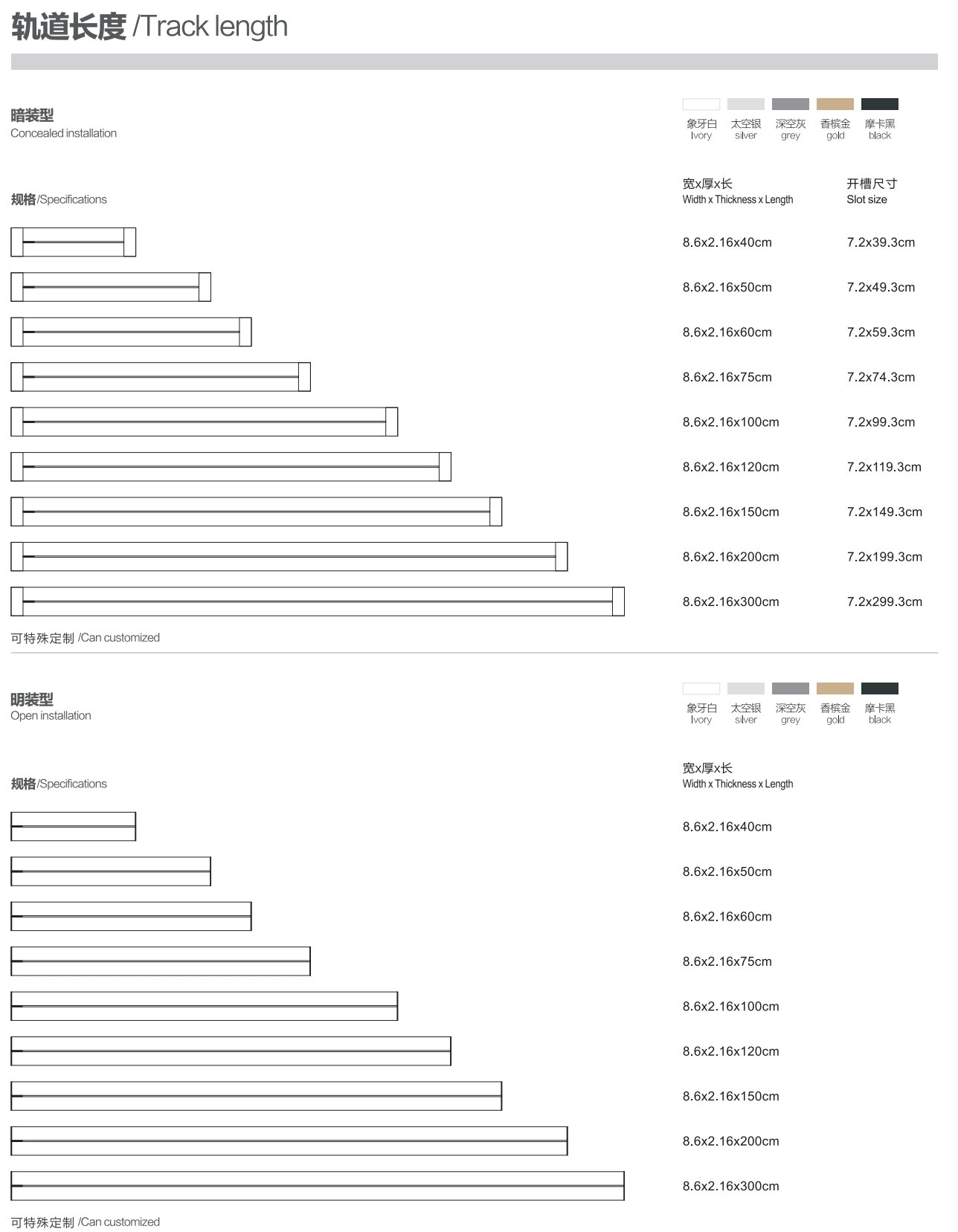

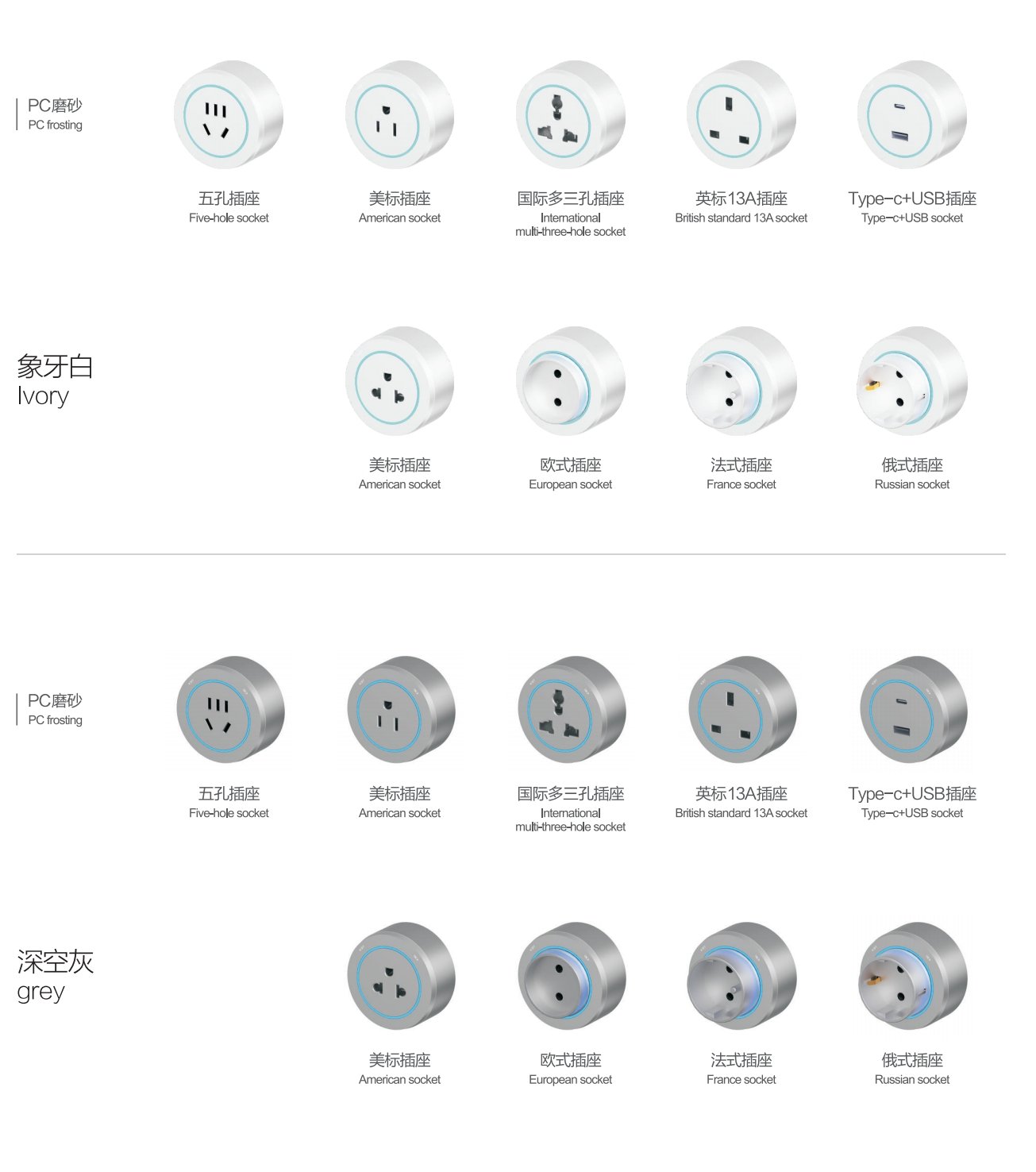

The track sockets are of two specifications. One is installed on the wall surface, while the other is hidden inside the wall.

The conventional length of the track socket is as shown in the figure below, and the length of the track socket can also be customized.

At present, we mainly promote the use of aluminum alloy material for track sockets. The module adapters of track sockets come in various materials, such as PC, aluminum alloy, etc. If you want to obtain more product information, you can contact us via email.